compression test cement|concrete psi strength chart : supermarket How do you test the compressive strength of concrete? Testing is the only way to determine whether a concrete mix has enough compressive strength, or load-bearing capacity, for the intended use. These tests are . We would like to show you a description here but the site won’t allow us.

{plog:ftitle_list}

webA solid jackpot and a high RTP of 97.16% provide a final incentive to spin, but we think the unique theme is what really sets this slot apart. Electric Elephant’s Volsunga slot game Fruits Go Wild. Fruits Go Wild is a traditional 3×3 slot with a fruit theme that will be familiar to all players, new and veteran alike.

Compressive strength of concrete depends on many factors such as water-cement ratio, cement strength, quality of concrete material, quality control during the production of concrete, etc. Test for compressive strength is carried out .The most common strength test, compressive strength, is carried out on a 50 mm (2-inch) cement mortar test specimen. The test specimen is subjected to a compressive load (usually . How do you test the compressive strength of concrete? Testing is the only way to determine whether a concrete mix has enough compressive strength, or load-bearing capacity, for the intended use. These tests are . Learn about ASTM C39 tests in construction and testing the compressive strength of concrete cylinders and ensuring structural safety.

The compressive strength test offers invaluable insights into the performance characteristics of concrete, informing decisions in design, construction, and quality control. By . The Compressive strength of a material is determined by the ability of the material to resist failure in the form of cracks and fissure. In this test, the impact force applied on both .

A concrete compression test measuring the resilience of hardened concrete is defined as the compressive strength of concrete. It is measured by analysing the concrete’s ability to .The compressive strength of cement is a measure of its ability to withstand axial loads applied to it, typically during the setting and hardening process. It is expressed in megapascals (MPa). .

portable nitrogen gas purity analyzer

The compressive strength test of concrete is a vital procedure to evaluate the strength and durability of concrete structures. The test is typically done on concrete cubes, and the results provide valuable information about the quality .

4. Pullout Test (ASTM C900) Method: The main principal behind this test is to pull the concrete using a metal rod that is cast-in-place or post-installed in the concrete. The pulled conical shape . Governed by standard C 39/C 39M, compressive strength tests are instrumental in assessing concrete's suitability for various construction applications. Test Methodology Scope. The standard test method is applicable to concrete specimens, molded cylinders, and drilled cores, specifically for those with a unit weight exceeding 50 lb/ft³ [800 kg .Table 1: Recordings during Compressive Test on Cement . 6. calculation; The measured compressive strength of the cubes shall be calculated by dividing the maximum load applied to the cubes during the test by the cross-sectional area, calculated from the mean dimensions of the section and shall be expressed to the nearest 0.5 N/mm 2.

The Australian Standard for determining the Compression Strength of Concrete (AS 1012.9) test uses a 200mm high 100mm diameter cylinder. The sample of concrete is compacted into the mould on-site, generally 2 samples are taken as a pair, and when applicable transported to a Laboratory for curing to Australian Standards.

The most common strength test, compressive strength, is carried out on a 50 mm (2-inch) cement mortar test specimen. The test specimen is subjected to a compressive load (usually from a hydraulic machine) until failure. This loading sequence must take no less than 20 seconds and no more than 80 seconds. Table 2 shows ASTM C 150 compressive .Compression testing is one of the most fundamental types of mechanical testing, alongside tensile and flexion tests. Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using platens or specialized .experienced in concrete technology. Factors contributing to the scatter of core strength test results include: † Systematic variation of in-place strength along a member or throughout the structure; † Random variation of concrete strength, both within one batch and among batches; † Low test results attributable to flawed test specimens or

Cubic or cylindrical samples of concrete are tested under a compression testing machine to measure this value. Test requirements vary by country based on their differing design codes. Use of a Compressometer is common. As per Indian codes, compressive strength of concrete is defined as: Field cured concrete in cubic steel molds (Greece) In addition, the 300K Concrete Compression Machine W/Pro-Plus Controller is the most popular choice for concrete test technicians and meets most test needs. . What is a compression test? A compression test is a type of mechanical testing that measures a material’s behavior under applied forces, usually conducted by applying pressure on a . The compression test measures concrete strength in the hardened state. Field concrete samples are prepared, cured and tested according to ASTM standard procedures. Specimens are prepared from concrete taken from different construction sites. Following processes and calculations are used for measuring compressive strength of cylindrical .

x Cylinders should be centered in the compression-testing machine and loaded to complete failure. The loading rate on a hydraulic machine should be maintained in a range of 28 to 42 psi/s (0.20 to 0.30 . curing and testing concrete test specimens will result in a lower measured strength. x The coefficient of variation between companion

The apparatus required for conducting the compressive strength test includes 7.06cm cube molds with a face area of 50cm², equipment for gauging and mixing mortar, a vibrator, and a compression testing machine. Procedure for Compressive Strength of Mortar. Measure 200g of cement and 600g of standard sand in a 1:3 ratio by weight. Concrete testing methods differ from place to place and each country has their own specifications that must be followed. While engineers and project managers in America adhere to the American Standard Testing Method (ASTM) C39 / C39M, Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens, those residing in Britain adhere to .

The test involves preparing test specimens of concrete cubes with even maximum load distribution before compression testing to determine the compressive strength of concrete. Factors such as water and cement ratio, aggregate type, and curing conditions affect the compressive strength of a material or commercial and industrial structures. 5.1 Care must be exercised in the interpretation of the significance of compressive strength determinations by this test method since strength is not a fundamental or intrinsic property of concrete made from given materials. Values obtained will depend on the size and shape of the specimen, batching, mixing procedures, the methods of sampling, molding, and .

Work with us to find the right equipment for your ASTM standard ASTM C109 | Concrete | Compression Testing Hydraulic Cement Mortars are typically formed by a combination of cement, sand, and water, but may include a variety of .1.1 This test method covers determination of the compres-sive strength of hydraulic cement mortars, using 2-in. or [50-mm] cube specimens. NOTE 1—Test Method C 349 provides an alternative procedure for this determination (not to be used for acceptance tests). 1.2 This test method covers the application of the test using either inch-pound or .

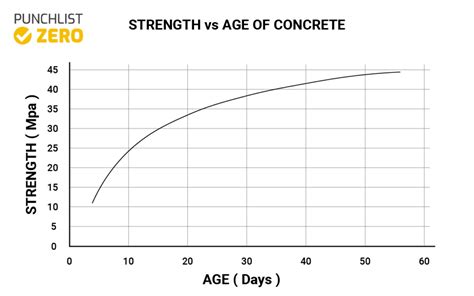

strength of concrete with age

According to section 19.2.1.3 of ACI 318-19 the specified compressive strength shall be based on the 28-day test results unless otherwise specified in the construction documents. 3- or 7-day test results are used to monitor early strength gain, especially when high early-strength concrete is used. However, 3- and 7-day test results are not .Read More: Tests on hardened concrete Compression Test and Slump Test for Quality Tests Among the tests mentioned above, the two major tests mainly considered as quality tests are the compression tests and slump tests. If necessary, it is desired to conduct fresh concrete temperature and hardened concrete density determination tests.The compressive strength of M20 grade concrete varies between 17 and 23 N/mm2 (i.e. between 170 kg/cm^2 and 230 kg/cm^2) after 28 days curing. This means that the concrete can withstand a compressive load of 170 to 230 kg/cm² before it fails.. In compressive strength test of concrete cube the push force applied on the both faces of concrete specimen and the maximum .Compressive strength test of cement is performed at the period mentioned below. For ordinary cement, after 3 days and 7 days. For rapid hardening cement, after 1 day and 3 days. For low heat cement, after 3, 7 and 28 days. The cube is tested by placing it under the Jaws of the compressive testing machine. The load is steadily and uniformly applied.

quiet portable gas generator

Compression testing of concrete cylinders is the final step in this process and is performed following the standard test method ASTM C39/AASHTO T 22. The prepared concrete test cylinders are placed in a concrete compression machine .

2. Compression Strength Test of Cement This test is done on 1:3 cement mortar cubes prepared by gauging 185g of cement 555g of standard sand and 74g of water. As per Indian standard specification, the average compressive strength for three cubes should not be less than 11.5 N/m 2 and 17.5 N/m 2 after 2 days and 7 days respectively.The MegaForce Concrete Testing System works with compression machines that operate up to 69 MPa or 10,000psi. Depending on the indicator chosen with the system, automated compressive strength test reports are generated, saving time as well as costs required to manually generate reports while decreasing the chance of errors. A compression test is a common method used in this process, and multiple compression tests can provide even more insight into a material’s strength and durability. Materials that undergo compressive testing include: . Concrete Compressive Test. In the context of concrete, compressive testing can be compared to a building undergoing a stress .

concrete strength chart uk

The unconfined compression test, also known as the uniaxial compressive strength test, assesses the unconfined compressive strength (UCS) of a concrete, cement, sand, clay, or soil sample under axial compressive loading. It is one of the simplest and most effective ways to assess the shear properties of a sample.

This video visually explains the process of the Determination of Compressive Strength of Cement-Treated-Base (CTB) Layer.Cement-Treated Base (CTB) is a type .

concrete strength chart time

O Fortune Mouse, conhecido também como jogo do Ratinho possui horários e minutos bom para jogar que a casa de aposta mais paga. Pensando nisso, separamos neste artigo os melhores horários pagantes do Fortune Mouse. Para ter acesso a plataforma oficial, segura e confiável do Jogo do Ratinho, Clique Aqui Horário Bom para Jogar o Jogo [.]

compression test cement|concrete psi strength chart